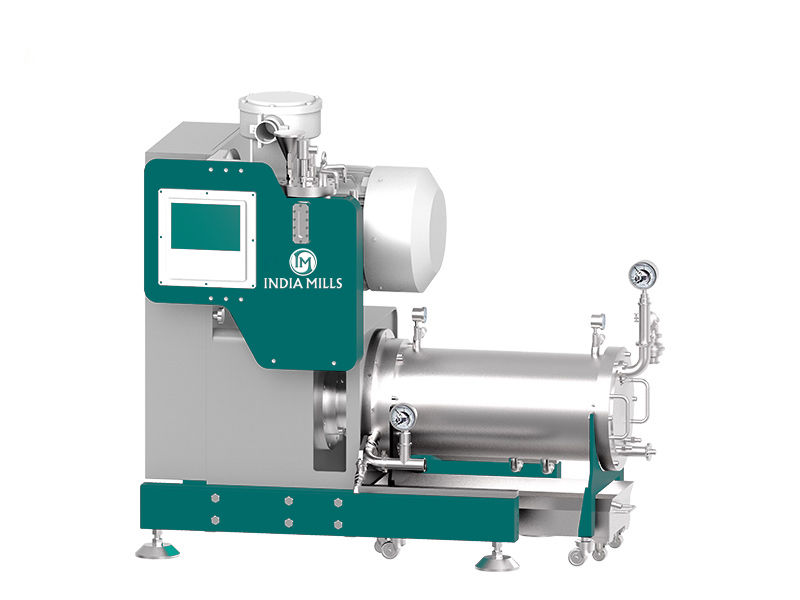

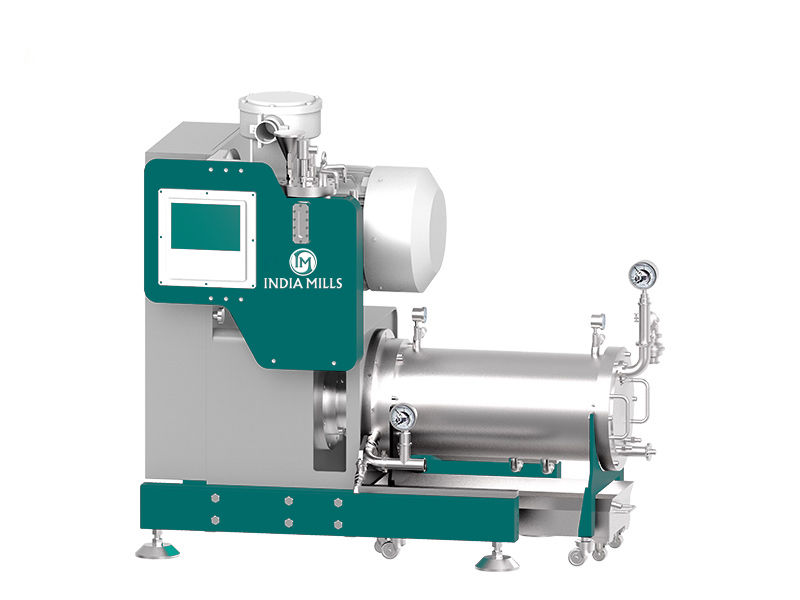

DHM Dry Grinding System

DHM system is Suitable for kinds of dry powder fine milling and classifying process which is with innovative integration equipment of dry grinding and classifying. High efficient Eco-friendly and Low consumption that guarantee the perfect performance of grinding micron to sub-micron fine powder.

DHM is the latest technology in Mills using Grinding Media for comminution.

Grinding Principle

The flow of air and powder to be classified within the selection enters the room through the supply opening (1), by effect of the vacuum created current on the outlet mouth (2) the flow of air and dust is forced to cross the dynamic selection of the rotor, where the centripetal force caused by rotation, ejects the coarse particles to the outside of the room and will be ejected by gravity from the bottom of the separator through a rotary throttle valve (3); the fineness of the product will be controlled by adjusting the rotor speed of the classifier using a frequency converter and by the parameters of pressure and depression of the air flow inside the classifying chamber

Operating Procedure

The material to be processed contained in the silo (1), is dosed through the conveyor (2), inside the mill (3), the rolling mill of the effect moves the grinding bodies (balls) contained inside the chamber of grinding. The ground product is extracted from the grinding chamber due to the vacuum created inside the piping (4), through which the product is conveyed to the first dynamic separator (5), inside the separator is a first selection of the powder, the coarse fraction (adjustable) is sent through line (6) to the mill, the end part is conveyed into the second dynamic separator (7) inside which is carried a further granulometric selection, the fine powder (finished product) is collected in the process filter (8), the second separator can be used to obtain two fractions granulometric (as in the diagram ....) or for an ultra-fine selection to obtain very fine final particle size (D 97 = 1 micron)

Technical Parameters