Fully Closed Production Lines

For Environmental protection, Enterprises need more automation and intelligence, and mass production of water-based coatings, paints and other products to meet this demand, we can provide a revolutionary "1+2+3..."Fully closed production line manufacturing process, can save ≥70% of the investment and operating costs.

From the initial contact, to technical exchange, and through design and manufacturing, on-site installation and debugging and other rapid response and professional support, we can integrate resources and have the experience of overall planning the entire engineering project. With cutting-edge technology and rich experience in the wet grinding field, we can provide you tailored solution (Turnkey Project) with your special order.

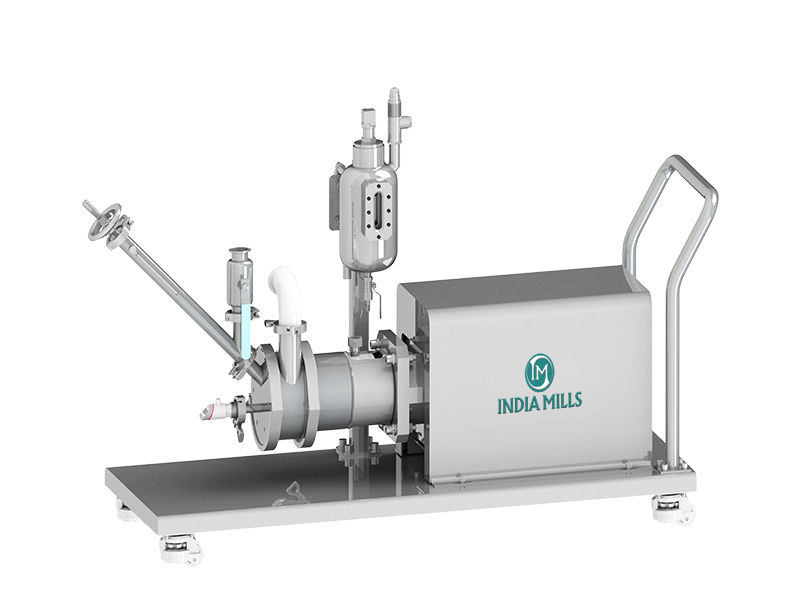

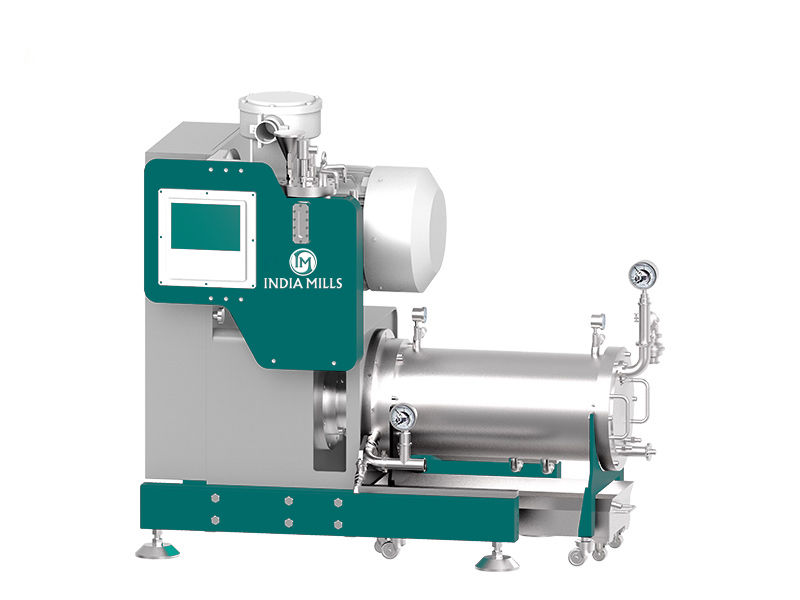

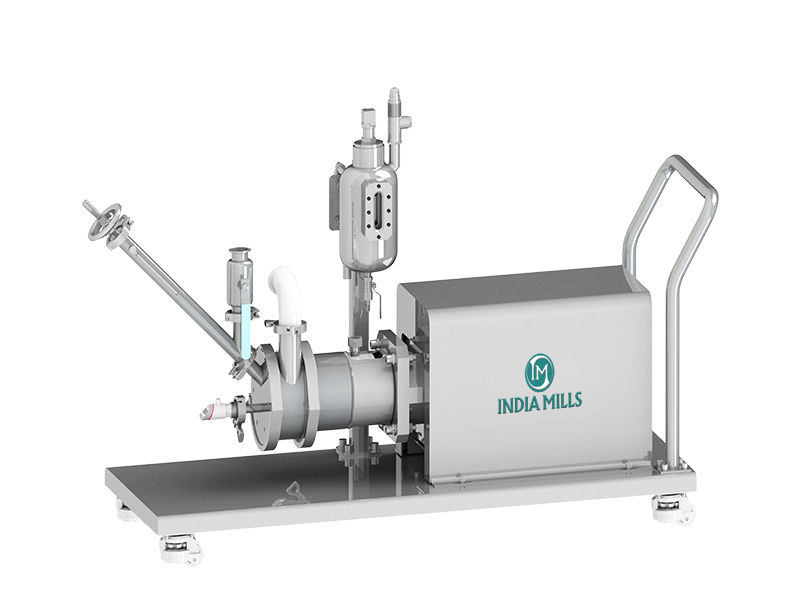

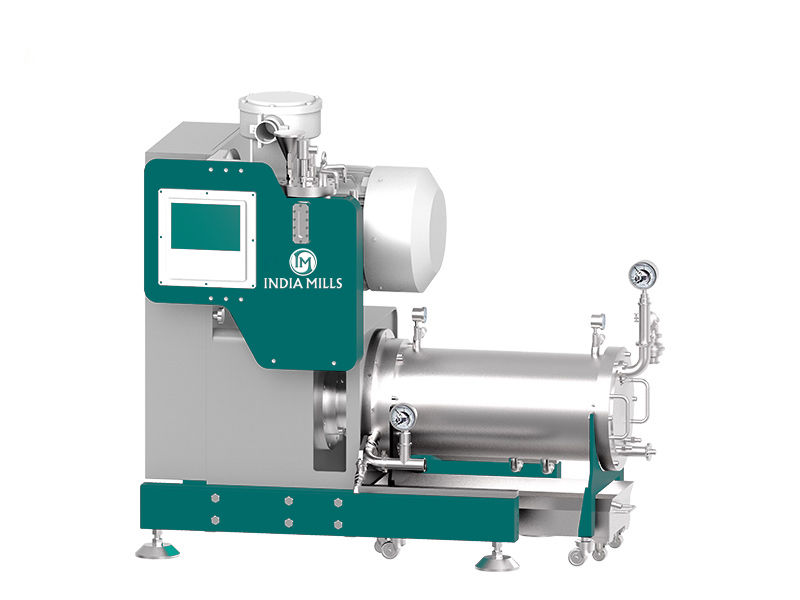

The batching system is composed of ton bag hoist (1) and powder storage bin (2). Use the pre-mixed ingredient tank (3)to ingredients, cooperate Inline powder-fluid mixing equipment IDM -H (4), its compact design, field advantage into full play, decrease the high-speed dispersion machine requirement for floors, it has the decentralized system in the vacuum airtight environment, thus there was no dust pollution and product loss, then can keep online system of product quality again. It can be fed through large bags or silos; For the temporary insertion order, the spare strong dispersing machine (5) can be selected for production. Coupled with a new generation of PIN/Peg type Bead Mill Kinet-Mill HPM- AC (6) was carried out on the blends of the pulp coarse grinding to ensure the steady output of products, to ensure that in the fine grinding stage discharge smoothly and avoid blocking separator device, grinding paste into the transfer tank (7) using series grinding process combination bar pin type Nano-Bead Mill HPM-P25 (8) nano lapping technology to non-destructive grinding products, paste into the finished product tank and then to filling system automatically by the pump to the packing.