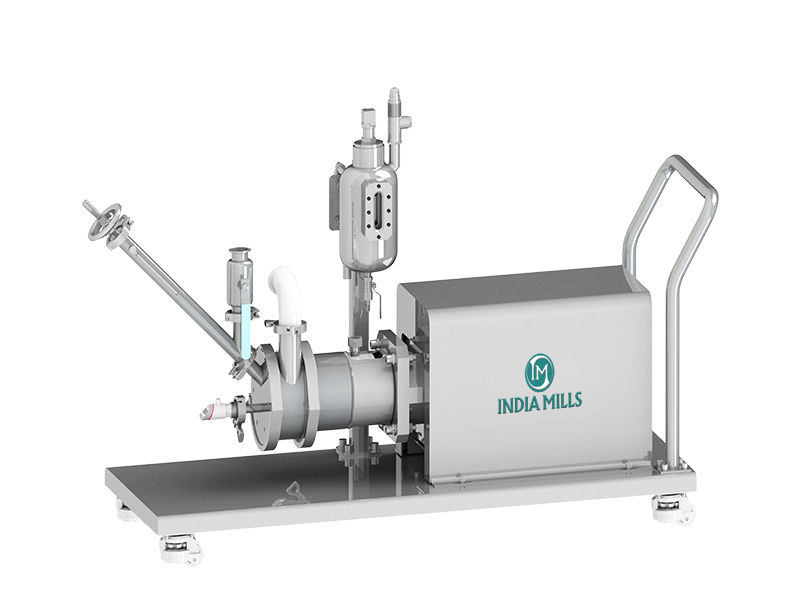

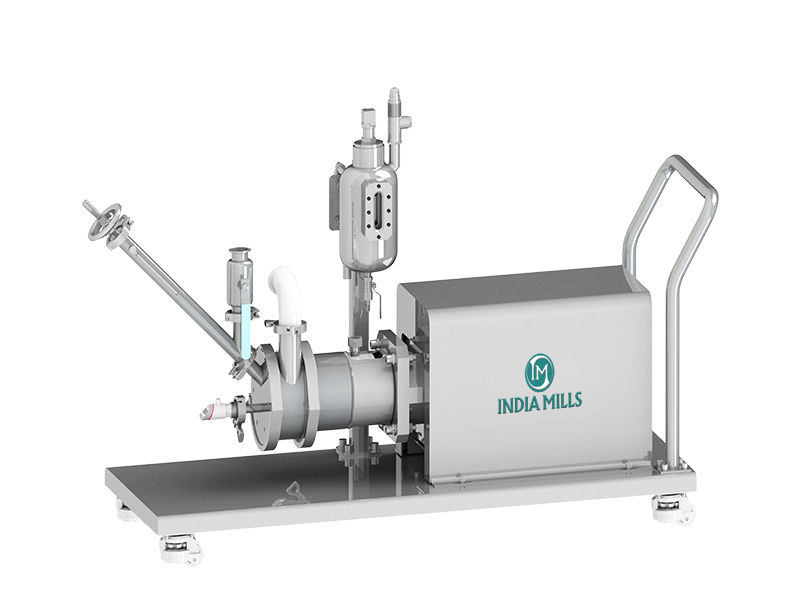

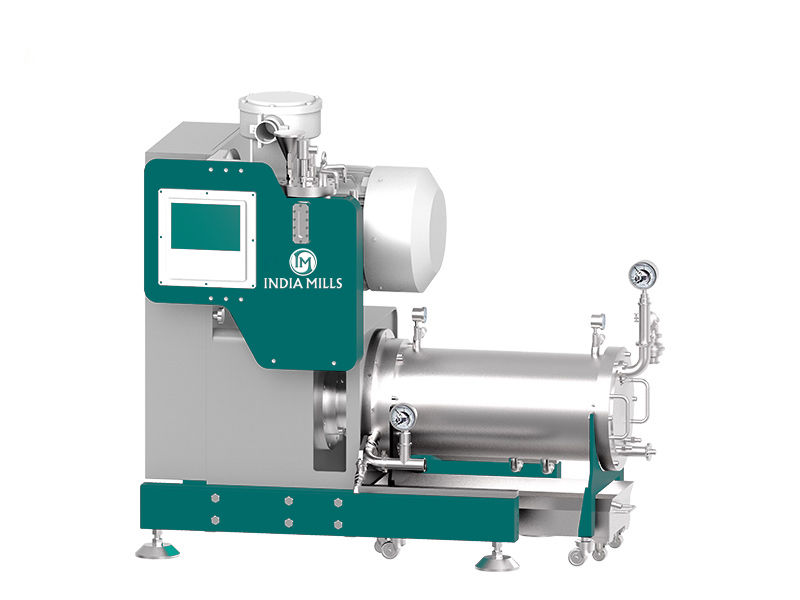

Eco-P enables the safe separation of grinding beads even at very high flow rates. Through the use of the highly efficient separation system, the extremely large size of the cylindrical centrifugal separator screen, the flow resistance (i.e., pressure drop) is the smallest. Smallest 0.05 mm discharge sieve can be applied.

Suitable for products with high viscosity, high solid content & high refining requirements for continuous circulating process operations.

Unique double cartridge mechanical seal ensures long operations of shaft seal, maximum 8-10 Kg pressure resistant.

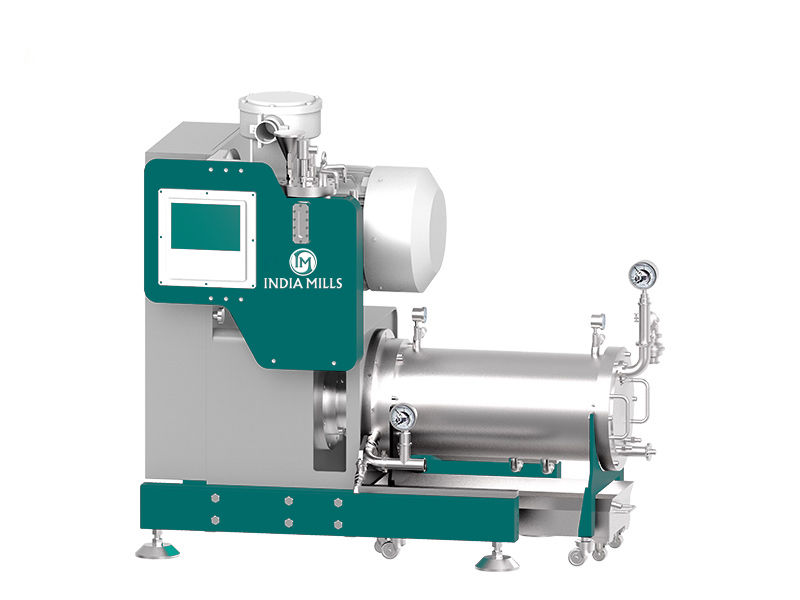

Features

Maximum slotted pipe surface area.

Optimised grinding media separation.

Maximum cooling surface to grinding chamber volume ratio.

New rotor design for efficient power input.

Optimum grinding chamber cooling with SSiC inner tank and optional rotor cooling.

The highest power input without overheating the product.

Maximum volume throughput.

The highest cooling efficiency.

Use of extremely small grinding beads (0.1 to 0.8 mm).

Reproducible product quality.

High degree of process reliability.

Low operating costs.

Conversion of existing machines to the latest technology.

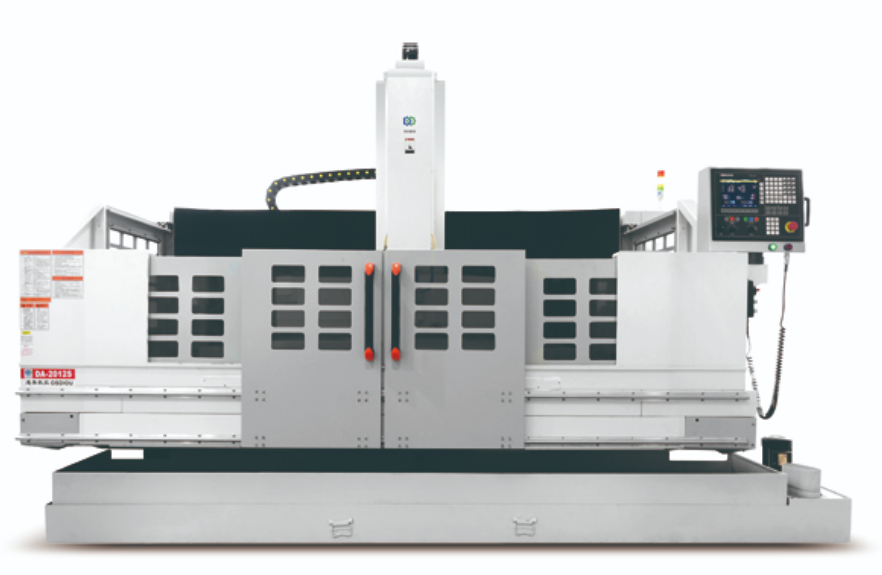

Technical Parameters