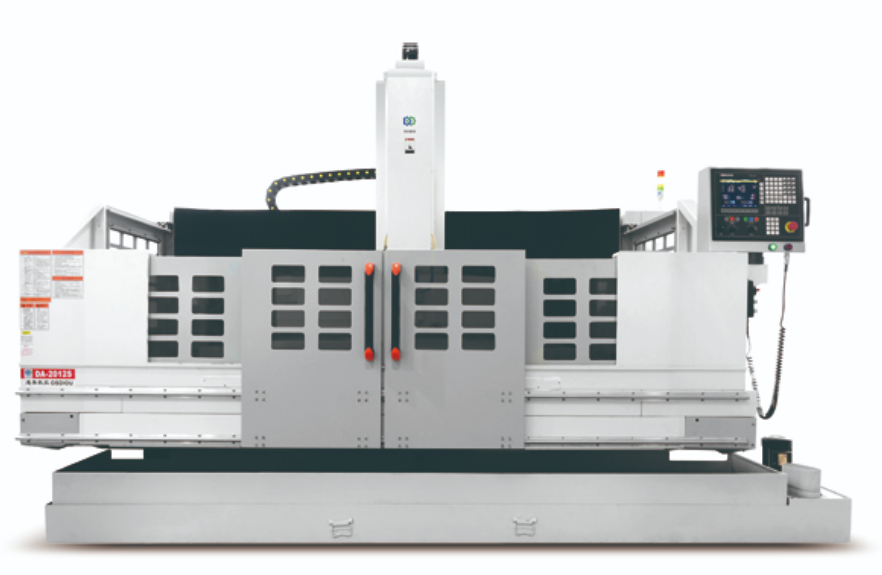

Grinding & Dispersing > High Performance Bead Mills > Kinet Mill HPM-D/DA Series

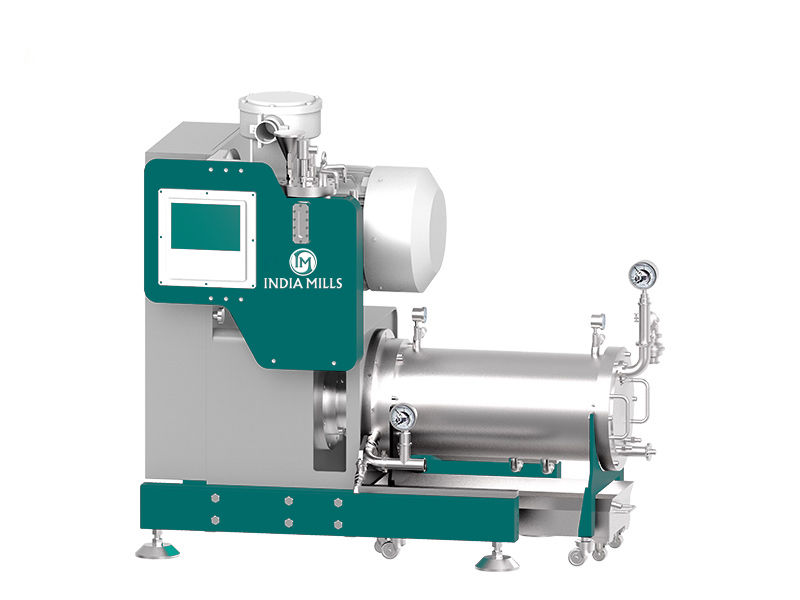

Kinet Mill HPM-D/DA Series

The innovative disk + turbine grinding system of HPM-DA has outstanding advantages on suspension liquid grinding. The technology enables the grinding medium not to accumulate when the output is increased. The overall optimized flow guiding spacer design achieves the optimal residence time distribution of the particles and the axial distance of the disk is optimal, forming a plurality of continuous grinding units, which flow through the material along the axial direction continuously.

In each grinding unit, the number of effective collisions between the material particles and the grinding medium is also greatly increased, so that the operation of the grinding medium is more powerful, and the circular running track is more reasonable.

HPM-D/DA includes a highly efficient reflective cage strip with multiple abrasive discs and dynamic classifier grinding system. In the reflective cage area, there have separation device for grinding media and materials. It adopts a rotor/slotted pipe separation system, which minimizes flow resistance (I.e. pressure drop), prevents the accumulation of grinding media, makes the flow in the chamber higher, and avoids wear of the separator.

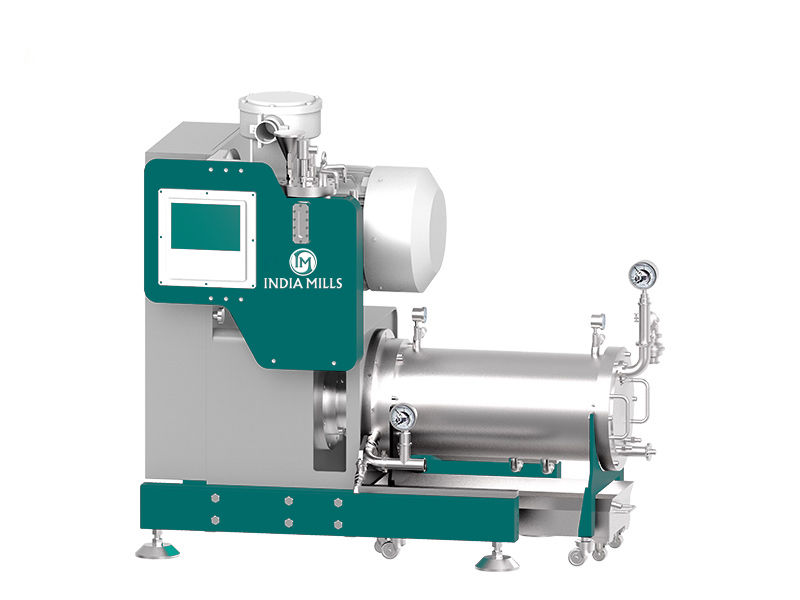

HPM-DA (Disc + Agitator System)

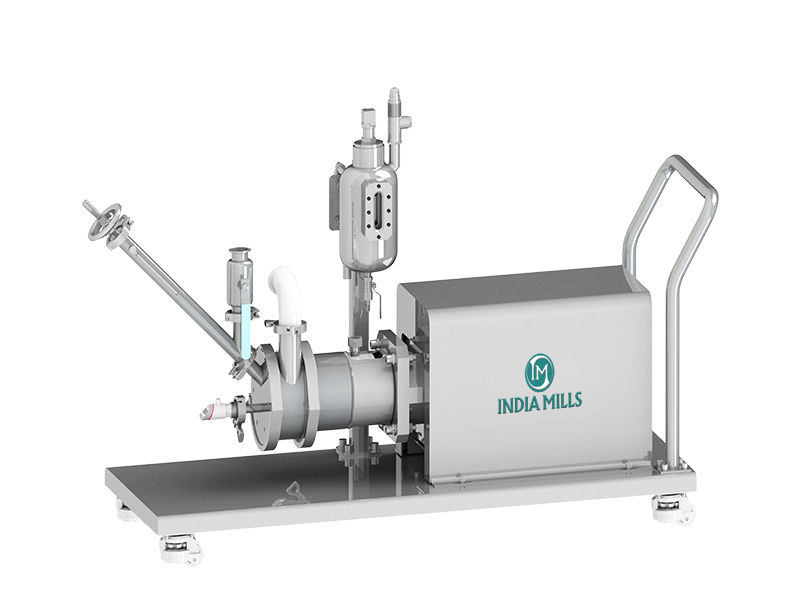

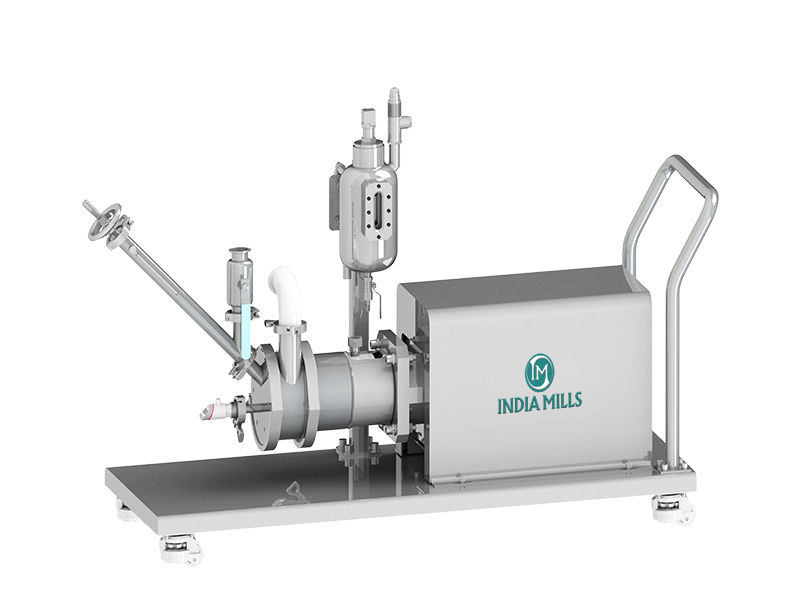

HPM-D (Disc System)

1.Cooling Water Inlet

2.Product Inlet

3.Agitator Disc

4.Beads Movement

5.Cooling Jacket

6.End Rotor

7.Screen / Sieve

8.Water Outlet

9.Pressure Release valve

10.Product Outlet

11.Temperature gauge

Technical Parameters