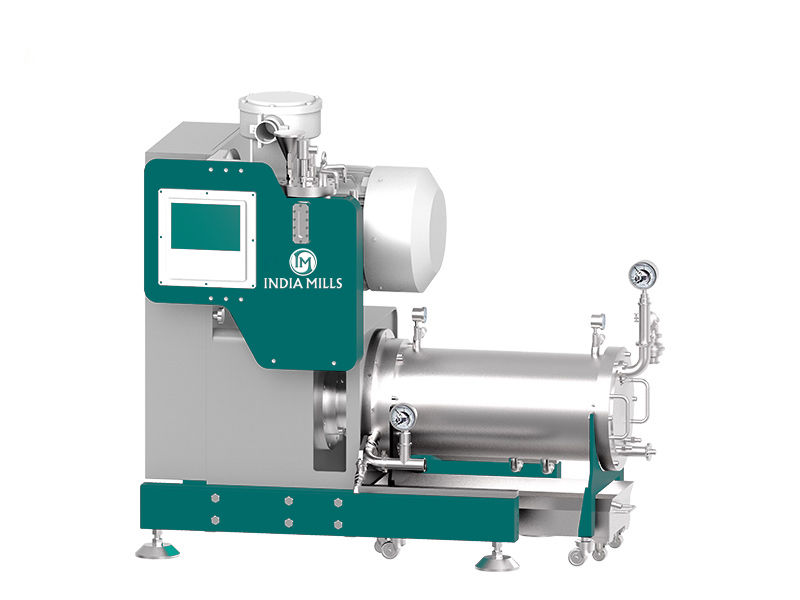

IDM-G consists of three components which are powder and liquid mixing system(IDM-C), grinding system (Accelerator) and emulsifying system, operated by PLC intelligent integration auto control.

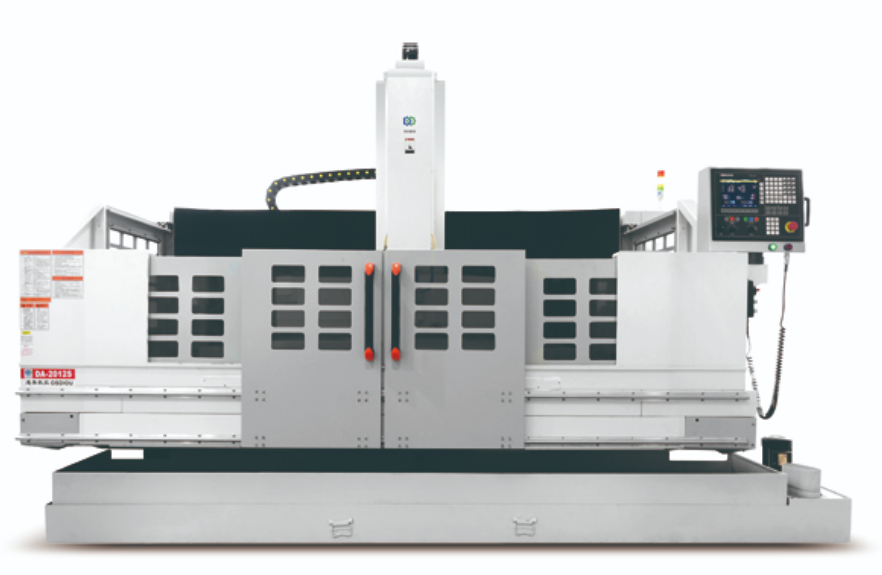

External dimension: 2604×1218×2000mm (Length×Width×Height)

1.Main motor : 2P-15KW 2

2.Grinding motor:4P-15KW

3.High shear and down-rotating Motor:4P-2.2/3KW

4.High shear and dispersion Motor : 4P-2.2/3KW

5.Powder and liquid mixing system

6.Grinding system

7.Emulsifying system

8.PLC integrated intelligent control

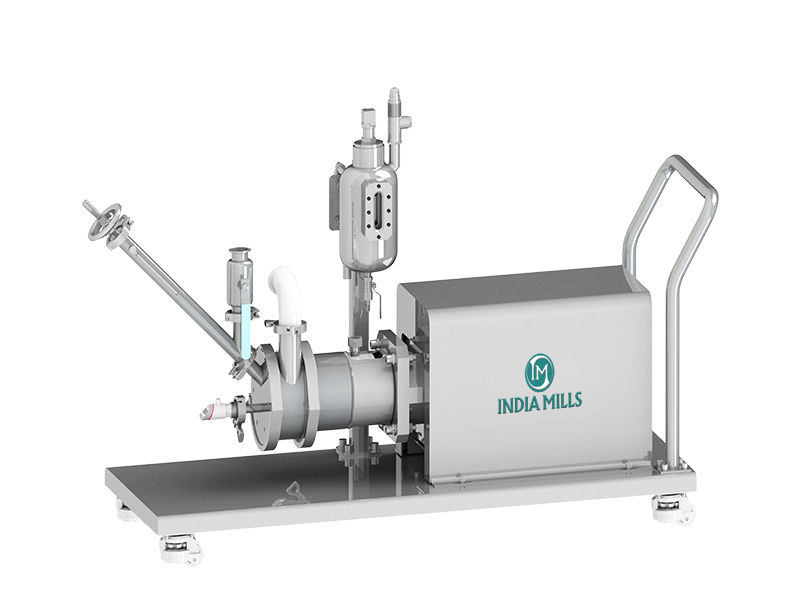

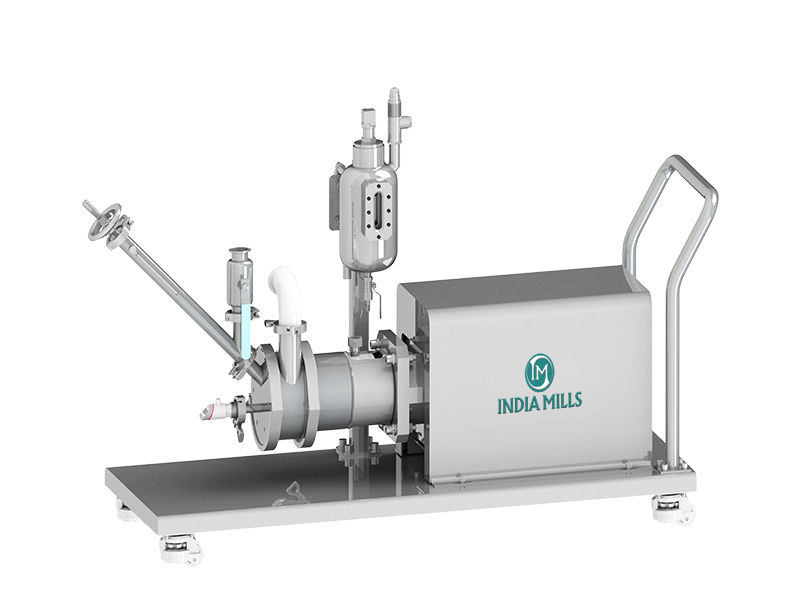

Powder and liquid mixing system

Inline disperser makes use of the working principle of high shear force rotor-stator. Narrow clearance between rotor and stator, and high liner velocity of external ring drives rotor and produces strong shear gradient and vacuum negative suction force. Product in rotor gears is forced into shearing area through grooves, and enters grinding system under the centrifugal force of stator groove.

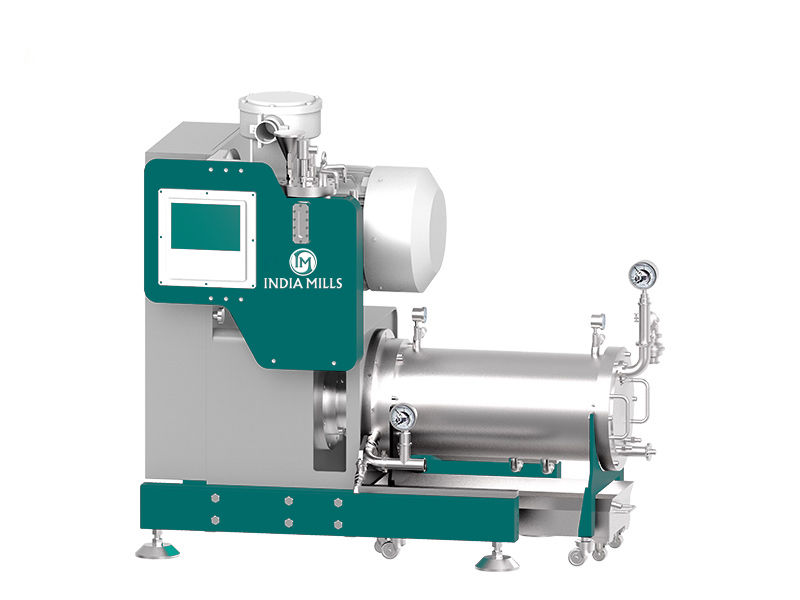

Grinding system

A Nano grinding mill with full-size and high efficient is the necessary part of this system, assuring high working efficiency, safety and reliability. Rotor with large radius produces vacuum self-absorption system with large absorbing ability, providing transmission force for the whole working station and providing power transfer solid and liquid slurry.

Emulsifying system

Mainly consists of jet flow dispersion rotor and axe high-shear rotor, jet flow dispersion rotor efficiently, rapidly and uniformly makes use of powerful kinetic energy brought by high shear peripheral speed and high-frequency mechanical effect caused by high-speed rotor to lead to integrative actions such as strong mechanical and liquid shearing, centrifugal squeezing, friction of liquid layer, collision and turbulence in the narrow clearance between rotor and stator. So that the insoluble solid phase, liquid phase, gas phase under the joint action of the corresponding mature process and proper amount of additives are dispersed and emulsified subtly at once, following a circle process in high frequency, and then axe high-shear rotor at high-speed absorbs material at the bottom of the kettle in dual way.