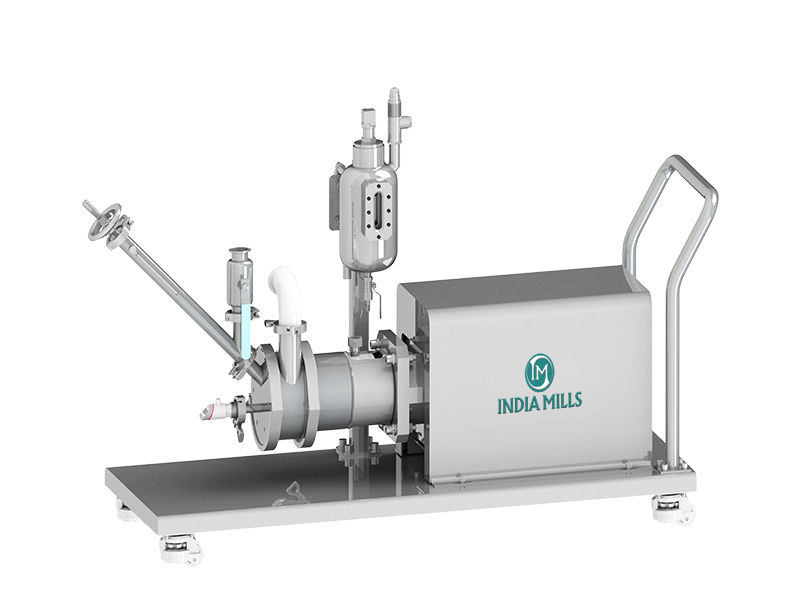

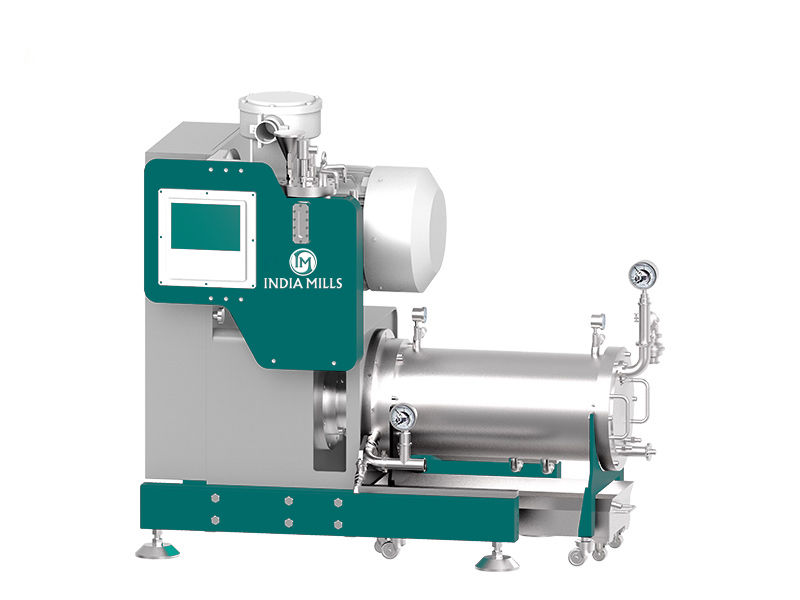

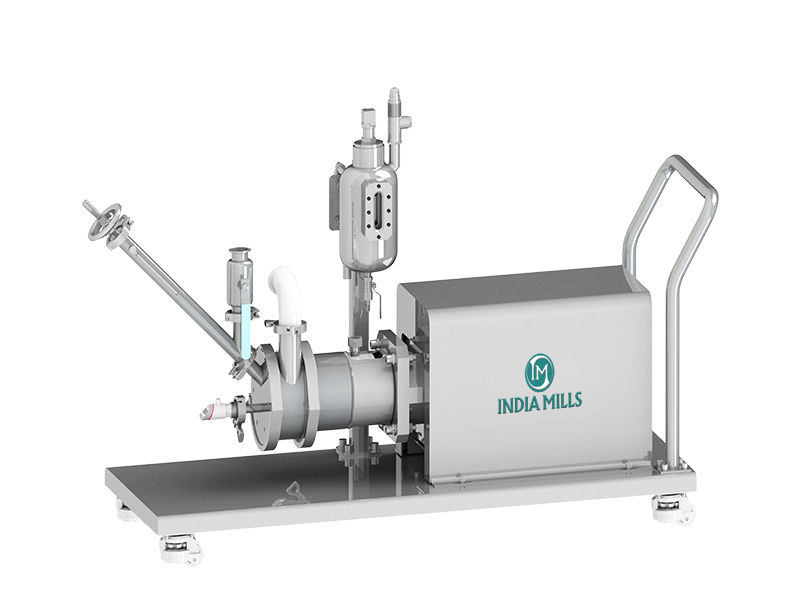

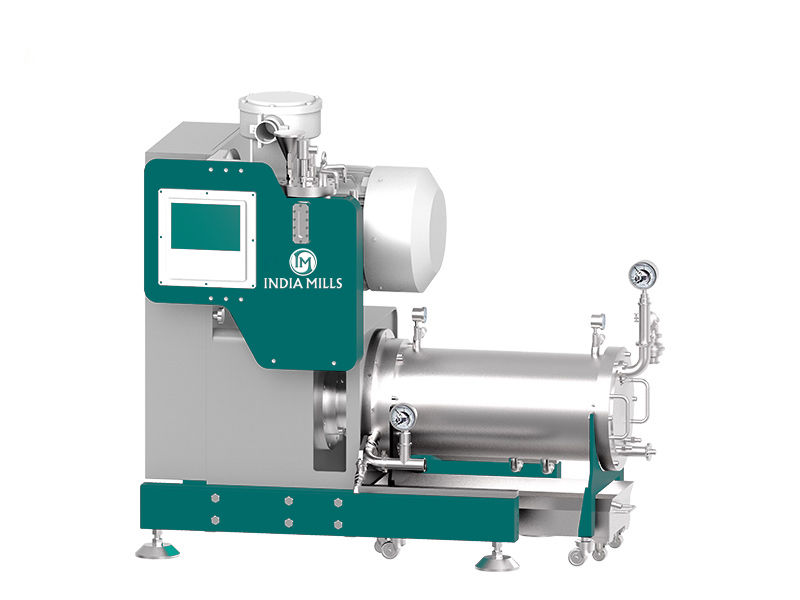

The IDM-C inline disperser produces vacuum through high frequency high-speed rotating of rotor, and uniformly absorbs powders from hopper or material bags to working chamber by suction & liquid (solvent or resin) from tank. Because of pressure differentia, the powder will be uniformly distributed and wetted in fast flowing liquid and humidified instantly without any agglomeration of any lump.

The wetting process is not based on the classic rotor-stator principle, by which dispersion is achieved through high shear rates. The principle of the IDM-C is based on the introduction of the powder under negative pressure in a continuous, large liquid surface. Due to the pressure gradient between the supply and delivery sides, the liquid is pressed into the agglomerate structure such that, within a very short period of time, the individual particles of the solid are almost ideally wetted. Because of the low shear rates, the energy input is significantly lower than for conventional rotor-stator systems, which means that a smaller increase in the product temperature is achieved.

Technical Parameters