Grinding & Dispersing > Inline Disperser > PreMx IDM-H

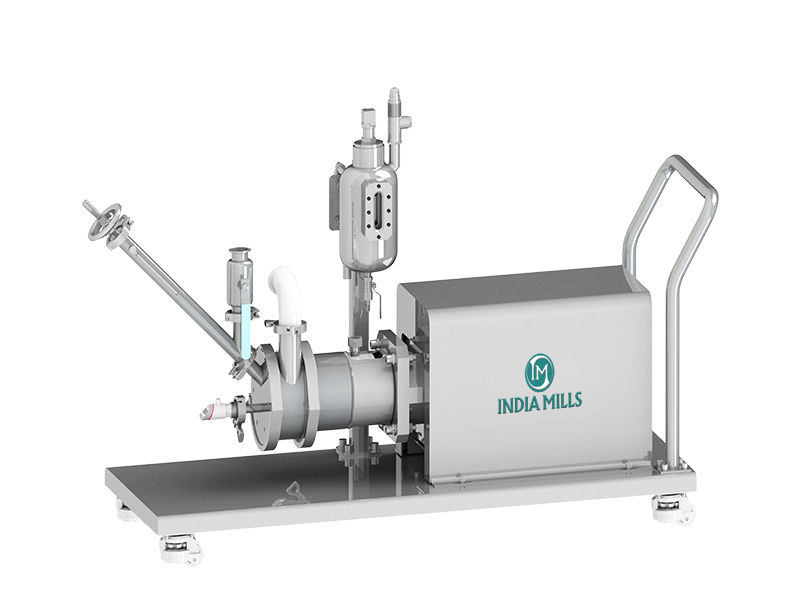

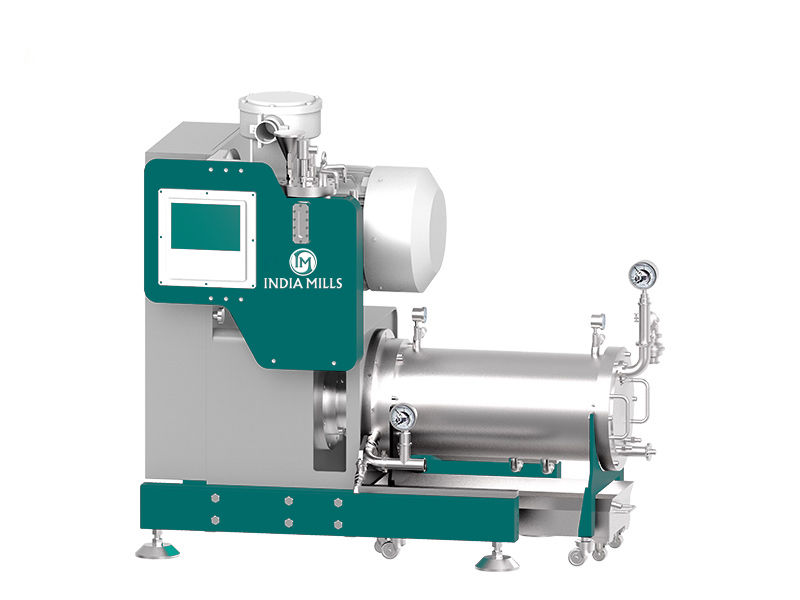

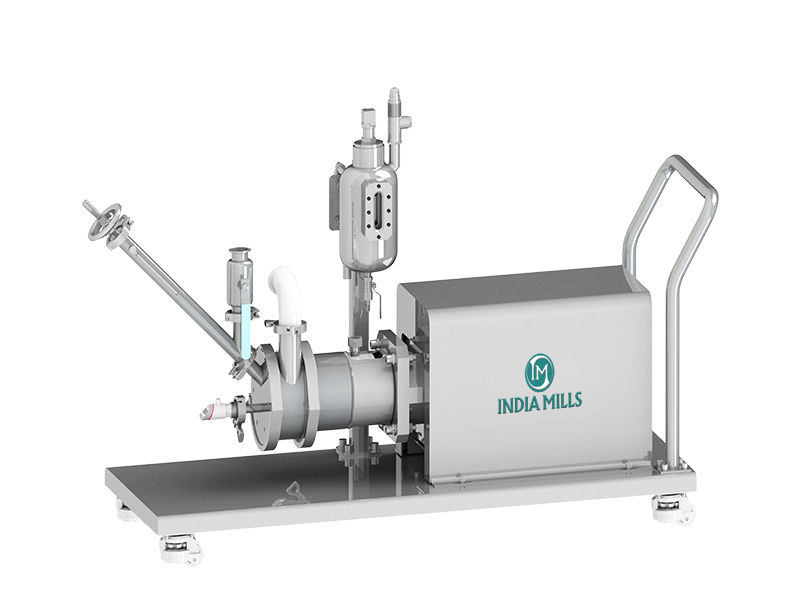

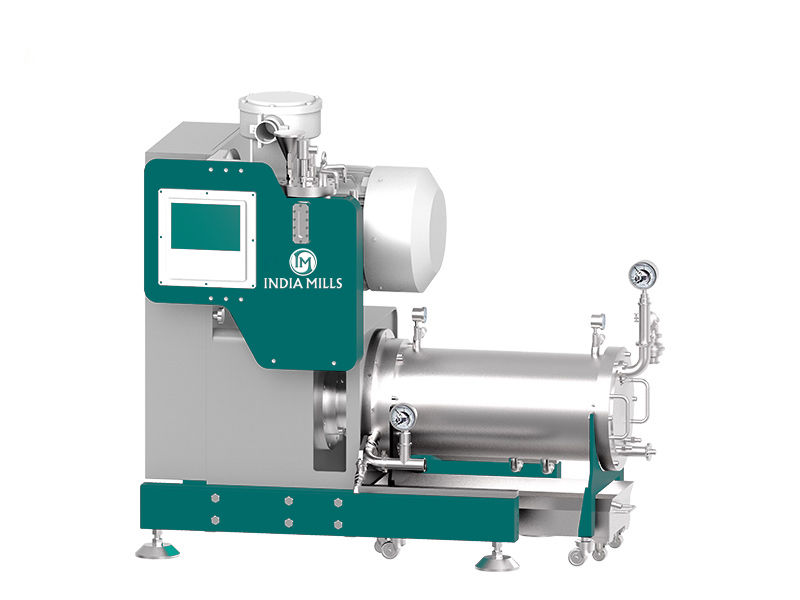

PreMx IDM-H

IDM-H system consists of a main body and an innovative turbine rotor, optimized through the calculation of the flow field simulation and fluid mechanics. It is mounted vertically. Through a double wall pipe, the material and the liquid are pumped into the mixing chamber separately from up and down directions for instantaneous wetting and dispersing, to avoid lump before entering the main body chamber. The liquid enters the wetting chamber at high speed, creating a vacuum at the centre of the rotor and stator to suck solids. The solids are evenly sucked through a star-type valve underneath the bucket tank. For solid packed with bags can be fed in through a suction gun or feed station, or it can be fed through a ton bag or cylindrical silo. The entire system uses the principle of inline wetting to achieve a unique integration of powder, emulsification, mild dispersion, convey and other unique function to a set of systems.

Break: scattered gear or scattered head and break apart materials, so that the large powder becomes uniform powder;

Vacuum: centrifugal pump suction effect creates vacuum and liquid spray creates vacuum;

Wetting: the gas inside the powder is taken away, and the liquid solvent is more easily allowed to enter the inside of the powder in the mixing chamber, so as to increase the humidifying effect of the powder;

Transportation: liquid is circulating, and a small amount of powder gradually mixes into it to dilute powder particles in the unit area;

High peripheral speed: the liner velocity is 30-50m/s. It can accelerate the turbulent diffusion and volume diffusion of the powder.

Applications: Optical materials, pharmacy, cosmetics, battery material, Nano application, agricultural chemicals, ceramics, glass, printing ink, pigment, dye, paints, oil paint, mineral, metal. Especially for: high liquid product, insoluble product, high solid content products.

Technical Parameters